Engineered Superior Design

Advanced Finishing Systems Design for Your Unique Process

We set our focus on customer’s process-specific needs. Our finishing systems are designed with a combined 90+ years of experience in electrocoat (e-coat) systems, powder coat systems, other industrial processes, and individual stage engineering and development.

All systems and individual stages are designed to meet or exceed our client’s needs. Additionally, we incorporate our own improvements that we use on all of our system designs. Call us or use our contact form if you have any questions.

Flat Panel Exterior

An overall improvement that we have made to our systems and stages is our flat panel exterior. Typically, these panels have their metal studs facing outward on our competitors’ systems.

Having these studs jut outward creates multiple hazards and impedes maintenance. The most noticeable improvement from having them turned inward is a system with an attractive luster.

This also allows for the outsides of the stages to be kept clean much easier.

Sharp edges, access door blockage, and area cleanup obstructions are all but eliminated.

Radial Bottom Tanks

Reliable drainage is essential for the proper operation of any system

Whether it be cycling out wastewater or cycling in liquid coatings, stoppages can cause serious production issues. Our washer and dip tanks are engineered with radial bottoms and sloped center channels. This allows for proper liquid flow and ease of cleaning because there are minimal areas for buildup. Gone are the leftover residue problems when switching production chemicals.

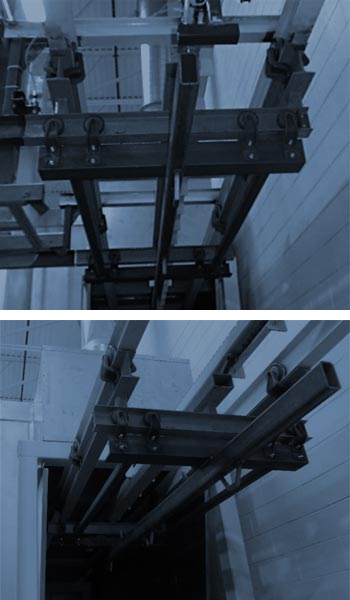

Motion Saver Systems

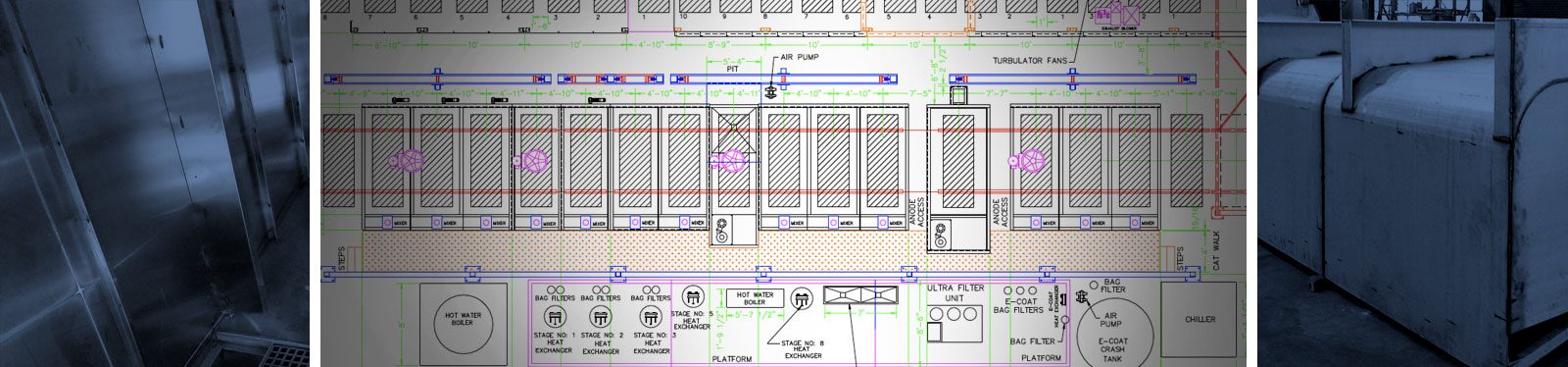

Enhance Productivity with Durusa’s Specialized Electrocoating Technology

Production floor space is a limited resource. In spite of that, production needs to meet the required quotas. Eliminate the need for space-consuming turns and diagonal product motion. Durusa designed “saver” systems utilize a unique horizontal transfer concept.

The rack on the indexing line lowers to dip loads and it lines up with the horizontal track. The load trolley quickly and smoothly slides over to the next stage in the process. The system saves space needed for transfer and production gets boosted by up to 20 loads per hour.

Improved Maintenance Access

We understand the frustrations of working in cramped, elevated spaces on production lines.

Inaccessible mechanical and pumping equipment can add significant time to already production-halting delays.

Our systems are designed with accessibility in mind. We have developed various system arrangements that allow maintenance teams access to pumps and other components from multiple sides. The end result is that you endure less downtime, avoid team-wide frustration, and gain efficiency through ease of maintenance.

Durusa designs: more efficient and easier to maintain

Call or contact us if you have questions. Provide some of your process-specific information about your e-coatpowder coat, or other finishing system needs and we’ll come back with solutions.