Precision Cleaning for Superior Coating Results: Durusa’s Parts Washers and Pretreatment Solutions

Parts washers and pretreatment systems see it all: Oxides, machine lubricants, residue from mechanical finishing and handling, everyday contaminants. The parts themselves also present issues: new alloy and composite materials, weldments, bonding agents and sealants also affect how cleaning and pretreatment should be accomplished.

The goal is to meet the cleanliness specification and provide the surface profile and adhesion qualities needed for the electrocoating, or powder coating, that follows.

Customized Parts Washers and Pretreatment Systems: Durusa’s Engineering Expertise

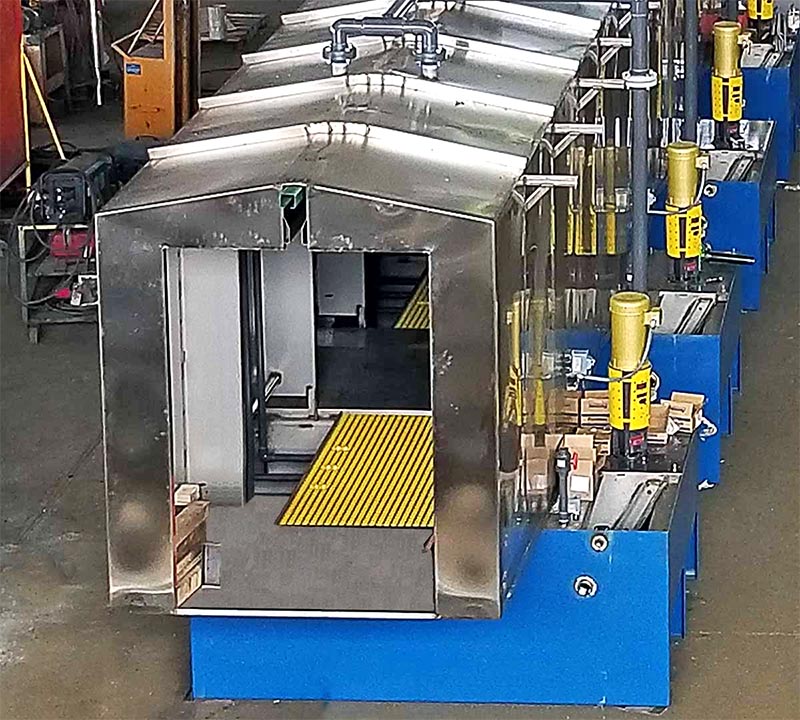

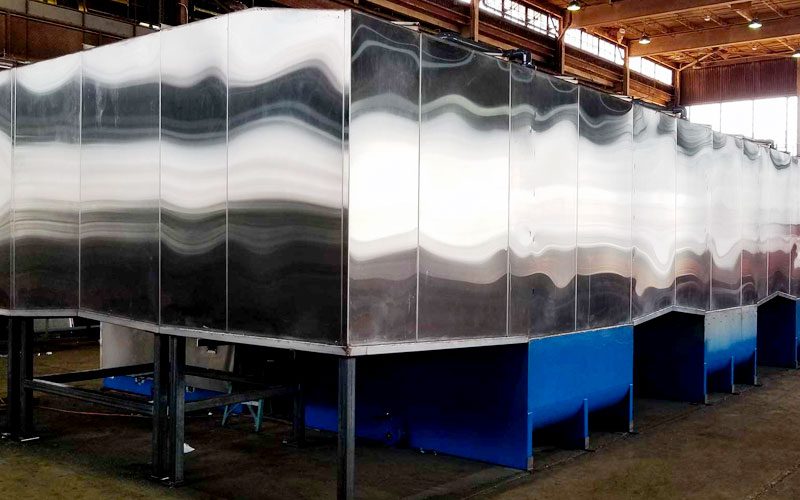

Durusa parts washers and pretreatment systems are engineered and built to meet your product needs, facility and budget limitations, production goals, and quality requirements.

Our experience in manufacturing these critical finishing line components runs deep. From tank design, agitation, recirculation and water removal to efficient filtration and waste management, Durusa has the track record to assure that systems operate at peak efficiency with minimal maintenance and utility expense.

Parts washers range from single-stage manual equipment to multi-stage robotic systems that yield chemically clean parts. Systems are factory-tested, wired and plumbed, installed, and commissioned by trained finishing line technicians, nationwide.

Our experts can assist you in determining the best industrial washing stages for your process

Call or contact usif you have questions. If you need a complete, Durusa designed finishing system, all washer stages are already included in the design