Powder Coat Systems

Durusa: Leading the Way with Advanced Powder Coating Systems

In earlier decades, powder coating systems replaced liquid coating lines thanks to then-new environmental requirements. Today, customers tell us that recent advancements in thermoset resins, and powder formulas that provide robust sharp-edge corrosion protection, are two of the main drivers when companies are contemplating a new powder coat line.

Durusa specializes in powder coating systems, custom-engineered for batch and automated processing. Systems can often be built to accommodate both types of operation.

What is Powder Coating?

Powder coating systems have been Durusa’s foundation since the beginning. We understand what works on paper vs. what works on the line. What equipment refinements work most effectively for metal vs. MDF vs. glass substrates. How to complement your existing liquid system when a process calls for dual coatings, and how to engineer a line to optimize shop labor.

From system design, fabrication, and installation, to part racking, system start-up and waste minimization, Durusa has the expertise to supply and support a powder coating line that is productive from Day One. It’s what we’ve done for dozens of OEMs, Tier 1s and powder coating job shops across North America.

• Powder Coating Lines • Mechanical Finishing Systems & Enclosures • Parts Washing Systems • Powder Pretreatment Systems • Powder Spray Booths • Powder Gel Ovens • Powder Cure Ovens • Power & Free Conveyor Systems • Hoists • Load/ Unload Stations

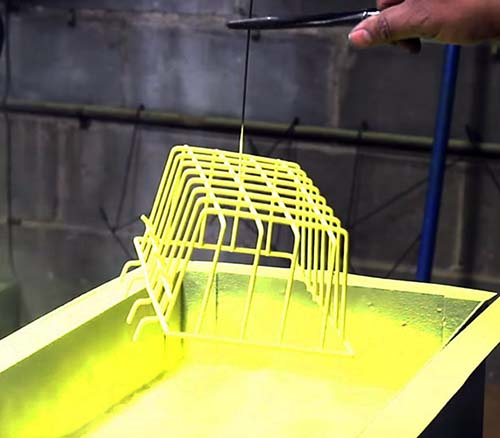

Fluidized Bed & Electrostatic Spray

Powder coat can be applied either by fluidized bed immersion or with an electrostatic spray. Either of these methods provide excellent product coverage and protection. Fluidized beds use gases forced into the powder to give it characteristics of a liquid. Greater coverage of a product is achieved by this simulation of liquid immersion.

Additionally, powder remains contained in the bed, minimizing material loss. Our electrostatic systems use a high voltage charge that attracts the sprayed coating to the product, ensuring higher transfer efficiency.

Unused powder gets collected to be reused in production, decreasing material loss.

Not sure which style best suits you? We’ll help you figure out which is best for your process.

.

Electrostatic Spray

- High voltage electrostatic charge greatly decreases overspray

- Quality corrosion resistance

- Large surface area coverage

- Cost-efficient

Fluidized Bed

- Full coverage of product due to immersion in fluidized powder

- Quality corrosion resistance

- No tooling cost

- Cost-efficient

Enhance Your Productivity with Durusa’s Specialized Powder Coating Technology

Call or contact us if you are interested in, or have questions about, a Durusa designed e-coat line.

Include a few details about your process and we’ll work to figure out the solutions. We also offer prefabrication and installation services to get your production line up and running.